|

ontrolling machine speed ontrolling machine speed

Another troubleshooting step that some printers overlook is how fast the press operates. By adjusting the speed of the machine, you will give the solvent more or less time to evaporate, which allows you to address changes in shop conditions. Slowing the press down will also reduce the amount of static generated by the pad.

The most common mistake people make is running their presses too quickly. Slowing them down can often improve the print quality and reduce rejects. Slow speeds allow more ink to be lifted from the cliche and deposited on the substrate. Also, machine vibration is reduced and the operator can monitor quality more easily. Remember, it's the number of good-quality items you print that matters, not the cycle time of the machine.

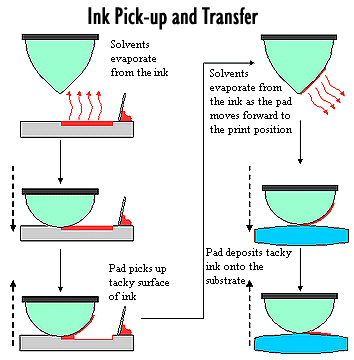

The most important parts of the press cycle to control are the pickup and laydown of ink. I would not consider buying an automatic machine that did not allow me to adjust the speed of these two steps (known as the dwell time). This feature allows you to fine-tune the printing process because the way the pad rolls on and off the cliche and substrate determine, to some extent, the amount of ink that is transferred.

Controlling the variables

The above isn't the only variable in the pad printing process. The key to successful pad printing is to control all of the variables which include: ink, pad, blade, plate, pretreatment, post treatment, etc.

Peter Kiddell

Peter Kiddell has been in the pad printing industry for more than 20 years and currently works as a pad and screen printing consultant. His company, PDS Consulting, develops training packages to help companies fine tune their pad printing process. He or his partner, Carol Burnside, may be contacted at |